Learn the history of the steam boiler

The steam boiler is currently one of the most essential pieces of equipment in many industrial projects. It is responsible for producing and accumulating steam that is produced through a heat exchange process between a fuel and water.

Like all equipment used in an industrial environment, the steam boiler has constantly evolved over time, allowing current equipment to offer maximum efficiency and operational safety.

But do you know the history of steam boilers and how they have evolved over the years? In this article, we will present a brief history of this type of equipment, from its inception to the present day.

First “steam boiler”: aeolipile

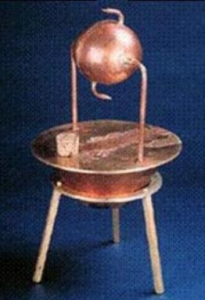

The steam boilers we know today became more popular with the industrial revolution, which took place in the second half of the 21st century. However, the “world’s first known steam engine” is over 1,800 years old and is known as the “aeolipila”. See the image below.

Developed by Heron of Alexandria, the aeolipile, also called a “wind ball”, basically consisted of a chamber (spherical or cylindrical) with curved tubes, through which the steam was expelled.

The resulting force caused the apparatus to rotate. Typically, water was heated in a basin connected to the rotating chamber by a pair of tubes that also served as the axis for the chamber.

For a long time the aeolipile was not scientifically studied, serving as entertainment, but this concept became the embryo of the steam boilers used today.

17th century: first steam boilers used in industrial environments

The first practical applications of a steam boiler in an industrial environment that we know of date back to the 17th century. In 1968, the Englishman Thomas Savery patented a water pumping system using steam as the driving force.

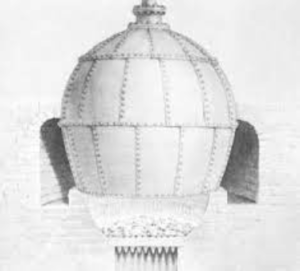

In 1711, Newcomen developed another piece of equipment for the same purpose, using ideas from Denis Papin, a French inventor. Newcomen's boiler was characterized by a spherical reservoir, with direct heating at the bottom, also known as a Haycock boiler (image below).

A little later (1769), James Watt modified the shape of the steam boiler slightly, designing the wagon-type boiler, a precursor to the boilers used in steam locomotives.

However, all of these models caused serious explosions due to the use of direct fire and the large accumulation of steam in the container. Thus, the rupture of the vessel caused a large release of energy in the form of expansion of the contained steam.

Convection Boiler: The Contemporary Roots of Today's Boilers

The contemporary roots of the steam boiler can be traced back to the late 1700s, with the development of the kettle boiler. But it was in 1867, with the development of the convection boiler, that the steam generation industry began.

The first equipment appeared primarily due to the need to replace coal in energy generation within industries, mainly because it had many drawbacks generated during its combustion.

Therefore, the first boilers with this purpose were represented by a central unit (the steam boiler itself), which distributed the steam to the machinery.

In the late 18th and early 19th centuries, the first water-tube boilers were developed. In 1880, Alan Stirling developed a bent-tube boiler, a design that is also used in modern boilers.

Biomass boilers: More modern and sustainable

The steam boilers currently used are responsible for providing sufficient amounts of energy to a wide variety of companies, mainly due to the use of cutting-edge technologies and high-quality materials.

And today, the current situation is demanding the search for maximum process sustainability. In view of this search, boiler manufacturing industries are already prioritizing the development of equipment with more sustainable characteristics, such as biomass boilers.

Currently, biomass boilers generate clean energy in sufficient quantities, using different types of biomass, such as wood derivatives and agro-industrial waste.

In the near future, the trend is to witness constant development of the steam boiler, which will inevitably involve better use of the calorific value of biomass, always focusing on maximum efficiency in the generation of steam for various industrial processes.

Now that you know the history of the steam boiler, we invite you to check out the entire MBX Blog where you will find everything from interesting facts to information and tips for your boilers!