What is the boiler quick discharge valve and what is its function?

Do you have a boiler in operation in your business? Then you certainly know the importance of periodically removing sludge and salts resulting from the settling of suspended materials in the feed water. To do this, the use of a boiler quick-drain valve is essential.

These valves are specially designed to be used to prevent the emergence of problems capable of affecting the efficiency of the boiler, such as the accumulation of sludge at the bottom of these steam generators.

See the importance of the boiler quick discharge valve and learn how this equipment works, allowing greater safety in the use of boilers.

What is a boiler quick blowdown valve?

The boiler quick discharge valve is a product specially designed to assist in the maintenance of pressurized equipment, vessels and boilers. This valve model is used to assist in the extraction of unwanted materials from the bottom of boilers, such as salts resulting from water decantation and sludge.

A quick discharge valve is designed to work under extreme working conditions related to the boilermaking segment. This valve has great structural solidity, in addition to a technologically developed finish, responsible for giving the boiler quick discharge valve an even more robust structure.

Why extract sludge and salts from boiler settling?

As already mentioned, the boiler quick discharge valve is used to help extract unwanted material, such as salts and sludge, which can accumulate at the bottom of the machinery.

But why should we extract these residues from the bottom of the boiler?

Boilers and steam generators are equipment that work continuously and always under high pressure, requiring the replenishment of feed water for their proper functioning.

Therefore, the continuous process of vaporization and water replenishment implies the formation and concentration of impurities in these steam generators. Therefore, to avoid excessive scaling on the walls of this equipment, the water is usually subjected to chemical treatment, modifying the nature of the impurities.

However, chemical treatment causes these impurities (suspended solids) to settle, settling at the bottom of the components in the form of sludge and settling salts.

However, excessive accumulation of these deposits can cause thermal stresses, which in some cases can crack the boiler walls or split the rivets. If this layer reaches the tubes, the stresses can be further aggravated by the consequent retention of heat, causing even more serious accidents.

Therefore, it is recommended that the sludge present at the bottom of the boilers be periodically removed. Thus, for this sludge removal to be as efficient as possible, the use of a boiler quick discharge valve becomes essential, thus ensuring proper operation and greater safety of the equipment.

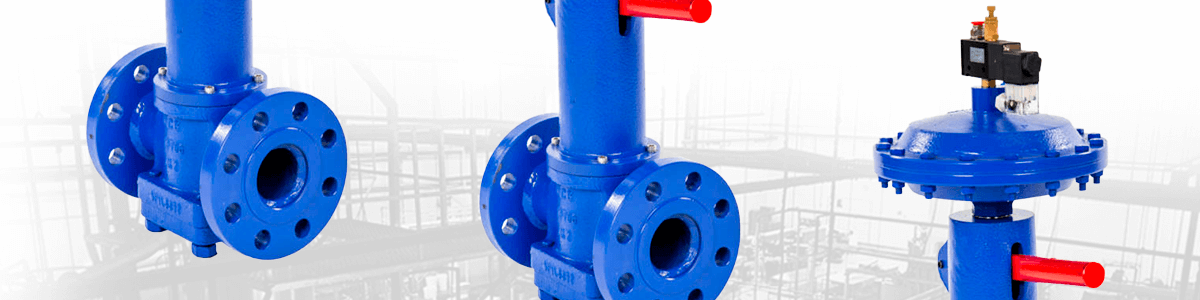

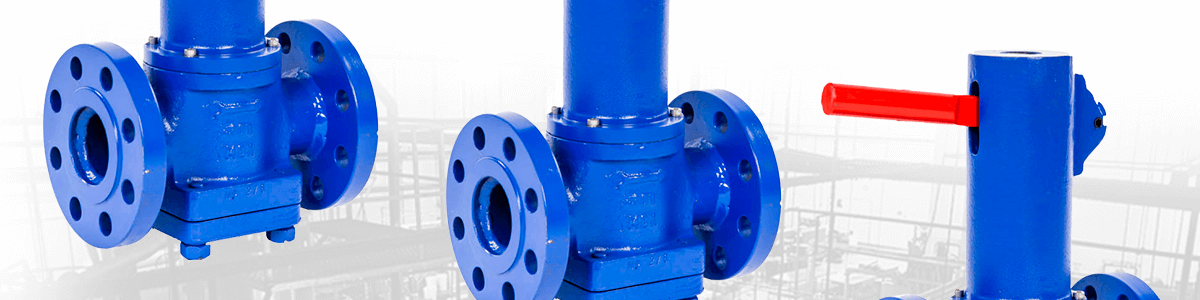

MBX Boiler Quick Blowdown Valves

Boiler quick discharge valves can have different types of action. Some models are manually operated or operated by air and water. These valves must have structural solidity, an efficient sealing system and a finish designed to withstand high workloads.

MBX, for example, offers various models of boiler quick discharge valves, both manual and automatic, as follows:

Manual models:

- MBX-40M 150/300 lbs;

- MBX-50M 150/300 lbs.

Automatic models:

- MBX-40A 150/300 lbs;

- MBX-50A 150/300 lbs;

- MBXSA-40A 150/300 lbs;

- MBXSA-50A 150/300 lbs.

These MBX discharge valves are manufactured in-house and 100% nationally, with the body, cover and bonnet manufactured with the best construction elements. This construction quality allows for greater thrust, generating greater drag and sludge removal.

It also features a special sealing system to withstand temperatures reaching up to 450ºC.

Finally, MBX boiler quick discharge valves have a significantly lower leakage coefficient when compared to globe and ball valves, approximately 50% to 75%, providing savings in water, chemicals, fuel and energy.

Want to know more about MBX products? Then get to know all the MBX product line .