Factors that damage boiler bottom discharge valves

Why install boiler bottom discharge valves?

In boilers, the progressive accumulation of scale can cause thermal stresses, causing cracks in the boiler walls or rivets. If this layer reaches the tubes, the stresses tend to be very serious due to the consequent retention of heat, causing their destruction.

For this reason, bottom discharge valves become essential equipment in boilers. Their main function is to remove sludge and residue that forms at the bottom of boilers and similar equipment.

By adopting this valve, the formation of scale on the equipment's components, plates and tubes is avoided. Therefore, there is greater heat exchange efficiency and a longer generator life.

However, as already mentioned, there are some factors that compromise, and even damage, boiler bottom discharge valves, as we will see below.

Factors that can damage boiler bottom discharge valves

As we mentioned previously, the periodic extraction of sludge and waste occurs through the action of boiler bottom discharge valves.

However, two problems that may occur in boilers can seriously damage the operation and efficiency of the valve.

The first of these factors is related to water treatment , more specifically its lack or inefficiency.

The second factor is related to the boilers themselves, specifically regarding metal fragments that can interrupt the proper functioning of the boiler bottom discharge valves, damaging them.

These valves suffer greatly from the deposit of metal fragments and other types of unwanted particles that may be present in the pipes.

Additionally, other factors can damage the valve, such as:

- Remains such as dirt and debris such as stones, pieces of steel, electrodes that are generally left inside a boiler after maintenance or assembly;

- Keep the movable lever for manual operation on the valve when they are being operated automatically. This will make it heavier and could damage the stem and seals;

- Misalignment and lack of support of the web where the valve is installed. This can twist the valve and damage repairs and seat.

- Water hammer (caused by incorrect angles, ignored when installing the system)

Solution: Installation of globe valves with filter

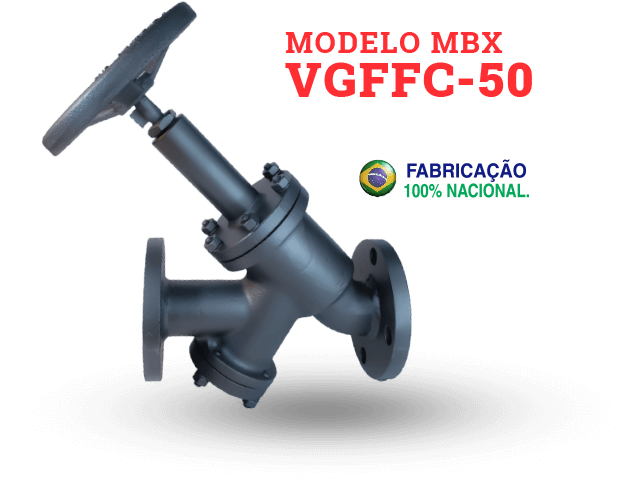

As a solution to help solve these problems, MBX has created a filter to be placed next to the globe valve . This globe valve with filter helps the industry to prevent the bottom discharge valve from being damaged by the problems mentioned.

Therefore, this device is widely used in boilers. They have several applications, such as flow interruption, isolation of certain points in the line, steam outlets and boiler drain points.

But, in addition to these possibilities, the globe valve with filter is responsible for helping to filter waste in boilers. It will also have a dual function of blocking before discharges, for possible maintenance and preventing boiler drainage.

With this device, cleaning the filter element becomes much faster and more efficient, in addition to preventing boiler bottom discharge valves from suffering unexpected blockages or being damaged.

Do you want to avoid treating your boiler's bottom discharge valve? Then use the MBX globe valve with filter! Click here and discover the features of this globe valve with filter!