Boiler Automation: See how to perform boiler bottom flushing

By automating the boiler, the industry can perform bottom discharge in a more periodic and less damaging manner. It also prevents the boiler from going too long without having the sludge layer removed, thus not compromising efficiency.

Why should boiler bottom flushing be carried out periodically?

In boilers, periodic sludge extraction is very important for the proper functioning and conservation of boilers. The main reason for this is to extract the sludge that accumulates at the bottom of the boilers due to the evaporation process and the consequent accumulation of impurities (solids).

When combined, these solids, together with the metals released from the boiler walls, form muddy water that settles at the bottom of the boiler. If the sludge is not discharged correctly and periodically, the boiler's efficiency will decrease, in addition to causing problems such as internal scaling in pipes, structural damage, and others.

In addition, excessive accumulation can generate other problems, such as thermal stresses that can cause cracks in the walls or damage to the boiler rivets. In more serious cases, it can retain excess heat, resulting in the total collapse of the equipment.

Boiler automation makes bottom discharge much more efficient

The fourth industrial revolution is a rapidly evolving process. Boiler automation is, within this scenario, one of the greatest representatives of Industry 4.0, mainly in the development of repetitive tasks that can be performed automatically by machines or systems.

By giving preference to boiler automation, the industry begins to enjoy a series of benefits such as: limiting the emission of pollutants into the atmosphere, also reducing the risk of work accidents and increasing management over production.

For the boiler bottom discharge , automation allows the optimization of this process, which will be more frequent, will have less damage and will be safer for operators.

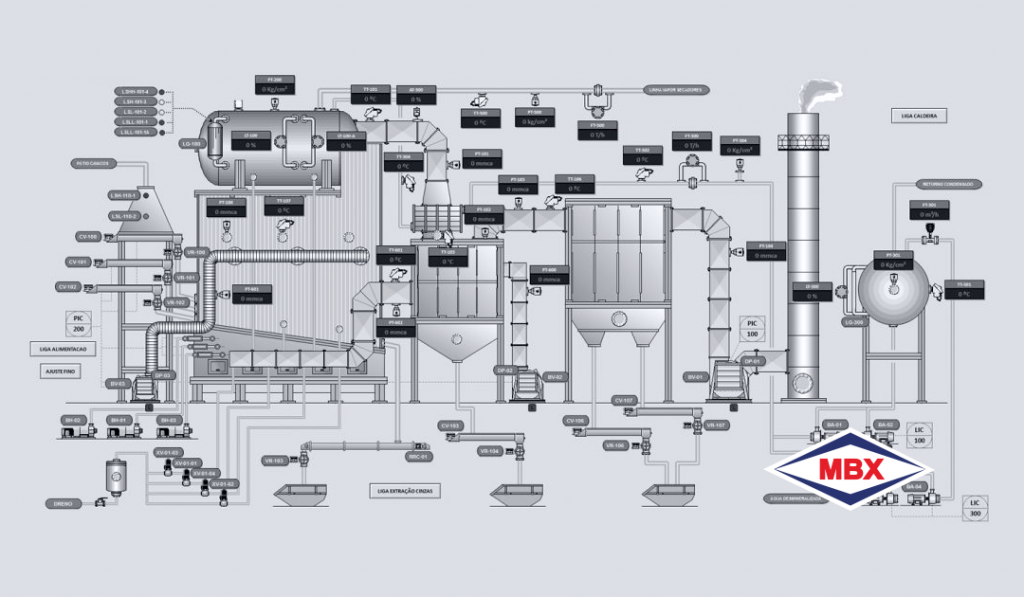

To promote this automation and adopt an automated bottom discharge system, simply place the monoblock ball valves with pneumatic actuator in parallel at the lower outlets of the boiler and connect them to an electronic timer.

After that, simply program the discharges at the time and period suggested by the engineer responsible for the technical operation of the boiler.

Benefits of automated bottom discharge in boilers

In addition to preventing the boiler from remaining inactive for a long time without having the sludge layer removed, boiler automation guarantees many other benefits, such as reducing heat loss to a minimum when unloading.

Automation also prevents unnecessary discharges. After all, without precise control over the recording of discharges made manually, the process can be carried out in duplicate, which is unnecessary and generates costs.

In addition to these benefits, automating boiler bottom discharge allows:

- Great energy savings and reduced boiler maintenance costs;

- Avoids wasting treated hot water;

- Prevents operating accidents;

- It offers gains in precision and regularity of interval and discharge times.

To learn more about the different types of boiler valves, we invite you to visit MBX blog .