Extend the life of your boiler by using a sludge extraction valve

Did you know that the useful life of the boiler also depends on the use of a sludge extraction valve? It may seem like a simple detail, but in steam generators, such as boilers, sludge extraction helps to prevent the formation of scale on components, plates and tubes, providing maximum heat exchange efficiency, in addition to a longer useful life for the boiler.

Therefore, it is quite interesting that you recognize the importance of the sludge extraction valve and how this device is essential to increasing the boiler's useful life.

Why should you use a sludge extraction valve on your boiler?

In boilers, the process of vaporization and water replenishment is continuous, but it involves the formation and concentration of many impurities. To prevent these impurities from accumulating on the walls of the equipment, the water is chemically treated, which can modify the nature of the impurities.

This treatment produces particles that settle and settle at the bottom of the boiler (cylindrical body and collectors) in the form of sludge. However, the progressive accumulation of scale can cause thermal stresses capable of cracking the boiler walls or rivets.

If this layer of sludge reaches the pipes, the tensions will be aggravated by the consequent retention of heat, which can reduce the useful life of the boilers and, in more serious cases, cause irreversible damage to the equipment, and may even cause total destruction.

To avoid these sometimes unpredictable problems, it is recommended to periodically extract the sludge, using a sludge extraction valve specially designed for this purpose.

When using this type of valve, sludge extraction will be much more effective and efficient, allowing for good operation and conservation of the boiler, enabling a longer useful life for this equipment.

Operation of the sludge extraction valve in a boiler

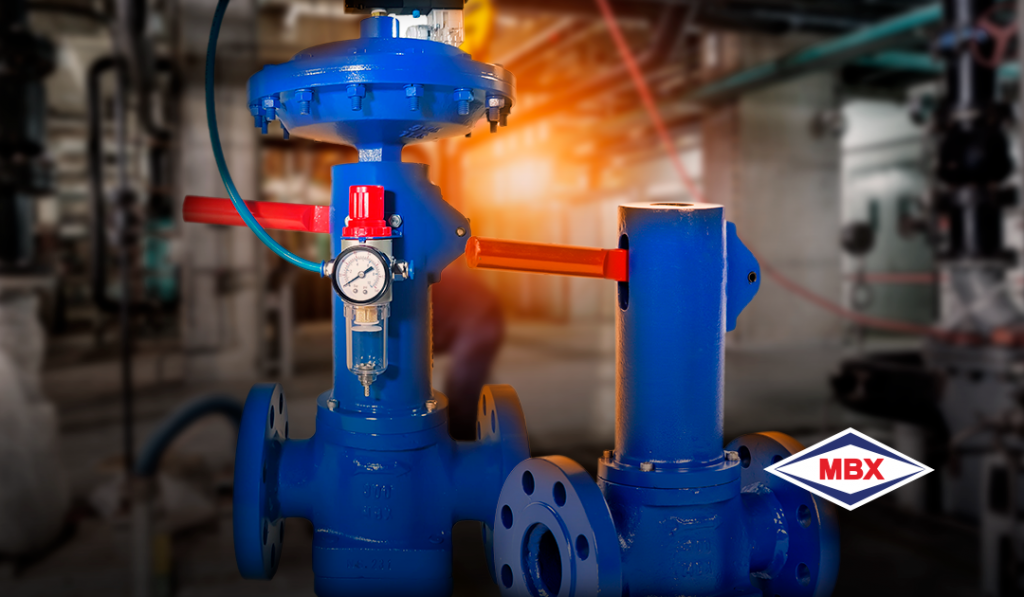

The operating process of a sludge extraction valve is relatively simple. To explain, we will take the sludge extraction valve manufactured by MBX as an example.

The construction model allows complete pumping of the boiler sludge with spiral drainage, thus avoiding waste of treated water. The valve also has a special seal, ensuring complete sealing on the stem and at the fluid outlet.

MBX also offers manual and automatic models, with on/off position sensor (valve opening and closing), offering excellent efficiency and safety during the boiler bottom discharge process.

Benefits of using the MBX sludge extraction valve

In order to ensure maximum safety and reliability, MBX prioritizes equipment innovation. A good example is the sludge extraction valve developed by the brand, which allows industrial plants to achieve many benefits.

As mentioned, the first benefit is the ability to have precise control over the elimination of sludge from the boiler, consequently improving the useful life of this equipment. Another factor that contributes to the longer useful life of the boiler is the special sealing system present in the valve, capable of withstanding temperatures of up to 450ºC.

In addition, the valve's construction means that it has significantly lower flow coefficients, especially when compared to globe and ball valves, approximately between 50% and 75%. As a result, there are savings in the consumption of water, chemicals, fuel and energy.

Therefore, in addition to prioritizing constant boiler maintenance to extend its useful life, it is an option to use a good sludge extraction valve, as this factor also contributes to its use without major problems resulting from sludge formation.

To learn more, we invite you to learn more about the MBX Blog!